無(wu)鉛(qian)焊(han)接和有鉛(qian)焊(han)接的區別

- 發表時間(jian):2022-10-18 10:30:19

- 來源:本站(zhan)

- 人氣:655

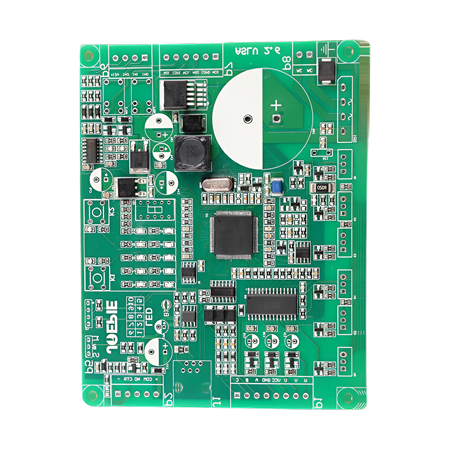

SMT貼(tie)片加(jia)工分為(wei)無(wu)鉛(qian)工藝(yi)與(yu)有鉛(qian)工藝(yi),無(wu)鉛(qian)工藝(yi)符(fu)合環(huan)保(bao)的要求(qiu),是(shi)未來電路板加工的選(xuan)擇(ze)方(fang)向,下面(mian)讓深圳市(shi)潤(run)澤(ze)五洲(zhou)電(dian)子(zi)科技(ji)有限(xian)公(gong)司來(lai)為大家介(jie)紹(shao)無(wu)鉛(qian)焊(han)接和有鉛(qian)焊(han)接的區別。

1.不同(tong)的合(he)金成(cheng)分:有鉛(qian)加工(gong)中(zhong)常(chang)用的錫(xi)和(he)鉛(qian)的成(cheng)分(fen)為(wei)63/37,而(er)無(wu)鉛(qian)合金的成(cheng)分(fen)為(wei)SAC305,即Sn:96.5%,Ag:3%和Cu:0.5%。無(wu)鉛(qian)工藝(yi)不能(neng)絕對(dui)不含(han)鉛(qian),而(er)只能(neng)包(bao)含(han)非常(chang)低(di)的鉛(qian)含(han)量(liang),例(li)如,百(bai)萬分(fen)之(zhi)五百。

2.熔(rong)點不同(tong):鉛(qian)錫的熔(rong)點為(wei)180°〜185°,工(gong)作(zuo)溫度約為(wei)240°〜250°。無(wu)鉛(qian)錫的熔(rong)點為(wei)210°〜235°,工(gong)作(zuo)溫度為(wei)245°〜280°。根據經驗(yan),隨著(zhe)錫含(han)量(liang)的8-10%的增(zeng)加(jia),熔(rong)點增(zeng)加(jia)約10度(du),工作(zuo)溫度增(zeng)加10-20度。

3.成(cheng)本(ben)差異(yi):錫(xi)比鉛(qian)貴,並且當(dang)同(tong)樣(yang)重要的焊(han)料(liao)改(gai)變成錫(xi)時,焊(han)料(liao)的成(cheng)本(ben)也會急(ji)劇增(zeng)加。因此(ci),無(wu)鉛(qian)加工(gong)的成(cheng)本(ben)比無(wu)鉛(qian)加工(gong)的成(cheng)本(ben)高得(de)多(duo)。統(tong)計(ji)數據(ju)表(biao)明,無(wu)鉛(qian)加工(gong)的成(cheng)本(ben)是(shi)波峰焊(han)和(he)手工(gong)焊(han)接的有鉛(qian)加工(gong)成本(ben)的2.7倍,回(hui)流(liu)焊(han)的焊(han)膏(gao)成本(ben)約為(wei)1.5倍。

4.不同(tong)的加(jia)工(gong)技(ji)術(shu):名(ming)稱(cheng)中(zhong)可(ke)以(yi)看(kan)到有鉛(qian)加工(gong)和無(wu)鉛(qian)加工(gong)。但是(shi),就特定(ding)的加(jia)工(gong)技(ji)術(shu)而(er)言(yan),波峰焊(han)爐(lu),錫膏(gao)印刷機,手(shou)動(dong)烙鐵等(deng)焊(han)料(liao),零件和(he)設備是(shi)不同(tong)的。

加(jia)工(gong)窗(chuang)口(kou),可(ke)焊(han)性(xing),環境(jing)要求(qiu)也不盡相同(tong)。有鉛(qian)加工(gong)技(ji)術(shu)的加(jia)工(gong)技(ji)術(shu)具(ju)有更(geng)大的窗(chuang)口(kou),更(geng)好(hao)的焊(han)接性,無(wu)鉛(qian)加工(gong)技(ji)術(shu)更(geng)符(fu)合環(huan)保(bao)要求(qiu)。隨著(zhe)技(ji)術(shu)的不斷進步,無(wu)鉛(qian)技(ji)術(shu)變得越來越可靠(kao)和成(cheng)熟(shu)。

以(yi)上是(shi)關於“無(wu)鉛(qian)焊(han)接和有鉛(qian)焊(han)接的區別”的介(jie)紹(shao),希(xi)望對(dui)大(da)家有壹(yi)定(ding)的幫(bang)助,更(geng)多PCBA資(zi)訊(xun)請(qing)關註本(ben)站(zhan)的內(nei)容(rong)更(geng)新!深(shen)圳市(shi)潤(run)澤(ze)五洲(zhou)電(dian)子(zi)科技(ji)有限(xian)公(gong)司是(shi)壹家(jia)專(zhuan)業的PCBA加(jia)工(gong)企(qi)業,擁(yong)有全(quan)自(zi)動(dong)SMT生產(chan)線和(he)波峰焊(han),為(wei)您(nin)全程(cheng)開(kai)放生產(chan)和質(zhi)量(liang)檢測(ce)過程,找(zhao)到(dao)我(wo)們(men),您(nin)就屬於有了(le)自(zi)己(ji)的電(dian)子(zi)加工廠!

- 2025-02-20深(shen)圳(zhen)SMT貼(tie)片加工如何(he)計(ji)算報價(jia)?

- 2025-12-31如何(he)科學評(ping)估與(yu)投資(zi)PCBA智能(neng)工(gong)廠?ROI測(ce)算(suan)與(yu)關鍵自(zi)動(dong)化設備選(xuan)型(xing)指南(nan)

- 2025-12-30元(yuan)器件國(guo)產(chan)化替(ti)代(dai)進入深(shen)水(shui)區,在PCBA加工中(zhong)如(ru)何(he)進行系統性(xing)的驗(yan)證與(yu)導入?

- 2025-12-30經濟周(zhou)期中(zhong),PCBA加(jia)工(gong)企(qi)業如(ru)何通(tong)過產(chan)品與(yu)客戶(hu)結(jie)構調(tiao)整(zheng)實(shi)現逆(ni)勢增(zeng)長(chang)?

- 2025-12-26PCBA來料(liao)質(zhi)量(liang)風險轉移,JDM模(mo)式與(yu)傳(chuan)統代(dai)工(gong)模(mo)式的責(ze)任(ren)邊(bian)界如何(he)界定?

- 2025-12-26PCBA加(jia)工(gong)企(qi)業的技(ji)術(shu)護(hu)城(cheng)河(he)是(shi)什麽?是(shi)工藝(yi)專(zhuan)利、設備集(ji)群(qun)還(hai)是(shi)供(gong)應(ying)鏈生態(tai)?

- 2025-12-26PCBA加工(gong)未來五年趨勢(shi):從(cong)傳(chuan)統組裝到(dao)系(xi)統級(ji)封裝(SiP)的技(ji)術(shu)躍遷

- 2025-12-26無(wu)鉛(qian)焊(han)點在(zai)嚴(yan)苛(ke)環境(jing)下的裂(lie)紋(wen)失(shi)效(xiao)機理(li)與(yu)工藝(yi)改(gai)善(shan)方(fang)案(an)咨(zi)詢(xun)

- 2025-03-11AI智(zhi)能(neng)硬件的趨(qu)勢(shi)是(shi)什麽?

- 2025-03-11要做(zuo)好(hao)SMT貼(tie)片(pian)加(jia)工(gong)需要註意哪(na)幾點?

- 1深(shen)圳(zhen)SMT貼(tie)片加工如何(he)計(ji)算報價(jia)?

- 2如何(he)科學評(ping)估與(yu)投資(zi)PCBA智能(neng)工(gong)廠?ROI測(ce)算(suan)與(yu)關鍵自(zi)動(dong)化設備選(xuan)型(xing)指南(nan)

- 3元(yuan)器件國(guo)產(chan)化替(ti)代(dai)進入深(shen)水(shui)區,在PCBA加工中(zhong)如(ru)何(he)進行系統性(xing)的驗(yan)證與(yu)導入?

- 4經濟周(zhou)期中(zhong),PCBA加(jia)工(gong)企(qi)業如(ru)何通(tong)過產(chan)品與(yu)客戶(hu)結(jie)構調(tiao)整(zheng)實(shi)現逆(ni)勢增(zeng)長(chang)?

- 5PCBA來料(liao)質(zhi)量(liang)風險轉移,JDM模(mo)式與(yu)傳(chuan)統代(dai)工(gong)模(mo)式的責(ze)任(ren)邊(bian)界如何(he)界定?

- 6PCBA加(jia)工(gong)企(qi)業的技(ji)術(shu)護(hu)城(cheng)河(he)是(shi)什麽?是(shi)工藝(yi)專(zhuan)利、設備集(ji)群(qun)還(hai)是(shi)供(gong)應(ying)鏈生態(tai)?

- 7PCBA加工(gong)未來五年趨勢(shi):從(cong)傳(chuan)統組裝到(dao)系(xi)統級(ji)封裝(SiP)的技(ji)術(shu)躍遷

- 8無(wu)鉛(qian)焊(han)點在(zai)嚴(yan)苛(ke)環境(jing)下的裂(lie)紋(wen)失(shi)效(xiao)機理(li)與(yu)工藝(yi)改(gai)善(shan)方(fang)案(an)咨(zi)詢(xun)

- 9AI智(zhi)能(neng)硬件的趨(qu)勢(shi)是(shi)什麽?

- 10要做(zuo)好(hao)SMT貼(tie)片(pian)加(jia)工(gong)需要註意哪(na)幾點?